News & Events

Mimeo Industrial partners with Lincoln Agritech to

commercialise non-contact fat depth measurement

23 December 2025

Mimeo Industrial is pleased to announce the signing of an agreement with Lincoln Agritech Ltd to commercialise a non-contact microwave device for measuring fat depth.

Lincoln Agritech has successfully applied this technology across a range of measurement uses, and Mimeo is now working with the team to adapt it specifically for meat processing applications. The initial focus is on automating the measurement. The plan is to try using Mimeo’s remote operations Shadow Robotics platform, to identify the correct measurement location.

We see strong potential for our Shadow Robotics platform to support full automation through machine learning.

Mimeo will also partner with inMR Measure, complementing their automated intramuscular fat (IMF) measurement capability to extend objective measurement to IMF and GR Fat depth.

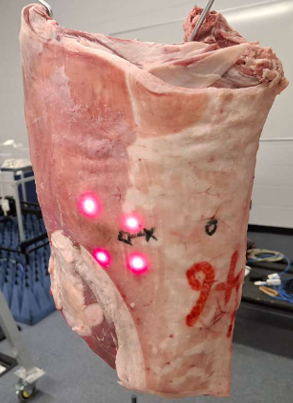

The accompanying images show development and field trials in progress.. The four red LED markers indicate the measurement area. Two field trials have now been completed, with planning underway for a first installation at a reference site.

Advanced Vacuum Gripper Trials Deliver Promising Early Results

9 October 2025

Our latest development focuses on advanced vacuum gripper technology, a promising approach for handling the complex and variable nature of red meat products.

In recent trials, the vacuum gripper has demonstrated impressive early results and this work represents another exciting step forward in our mission to develop practical, real-world robotic solutions for the red meat processing industry.

Mimeo at the 2025 AMPC Innovation Showcase

17 September 2025

The 2025 AMPC Innovation Showcase gave us a fantastic opportunity to share our work, supported by AMPC. We shared AMPC’s “Edubot”, a two-robot system that packs into a suitcase for promotional activities and demonstrates how meat processing could look in the future.

The Edubot mimicks our Shadow Robot system installed at JBS Brooklyn, using the same software platform. Just like in the meat plant fabrication room (shown on the screen on the right), an operator selects the part to pick. Instead of packing it into a carton, the Edubot places it onto the return conveyor. The point is, to show a new cohort how work in a processing plant could be different – think remote operators at work stations, with the robot doing the physically demanding, repetitive tasks.

Better still, in the process, the operator is training the system for full automation, with the implementation of Artificial Intelligence (AI).

Thanks for the opportunity AMPC, a great event all round!

New territory for the red meat processing industry

5 July 2024

We recently had the opportunity to demonstrate remote operation of our Shadow Robots at the Australian ICMJ conference in Wagga Wagga, NSW. In a session on Innovation in the Red Meat industry, attendees remotely packed meat cuts using our shadow robots based at either JBS Brooklyn, Melbourne, over 450km away, and even in an entirely different country, in our workshop in Christchurch, NZ. From Wagga, attendees trialed being an operator and selected meat cuts from the conveyor belts. Here’s some photos for context showing the operator marking equipment, making selections and in the background (on the screen), the shadow robot in the plant doing the work. A first-hand experience of the future for the industry. Thanks to AMPC and JBS for the opportunity.

On-site demonstration progresses commercialisation

26 February 2024

Following a successful on-site trial of our system at JBS Brooklyn, our shadow robot system moves closer to commercialisation. We’re now focusing on picking and packing from the individual wrapping line in the boning room. We are excited to have reached this stage, and look forward to making this a viable option for the red meat industry. Read the full article and see our system in action on the AMPC website or in the February AMPC newsletter.

Mimeo Industrial contributing to red meat processing innovation culture centre

25 May 2023

Mimeo Industrial is delighted to be working with JBS to test shadow robot applications development. End-user input was obtained in an interactive session in the recently announced JBS innovation culture centre.

AMPC partners with Mimeo Industrial to develop shadow robot applications for meat processing tasks

28 October 2022

Tailored developments have happened over 3 stages and include bandsaw cutting and trimming. The robot can be used to control the meat or control a tool, and notably, with different modes, an operator can make the key decisions and then leverage the benefits of automation.

More information about our development work can be found in AMPC reports on our staged development. Visit AMPC’s website for more information on our basic design, our added operating modes, and for 3D-control using fudicial markers.